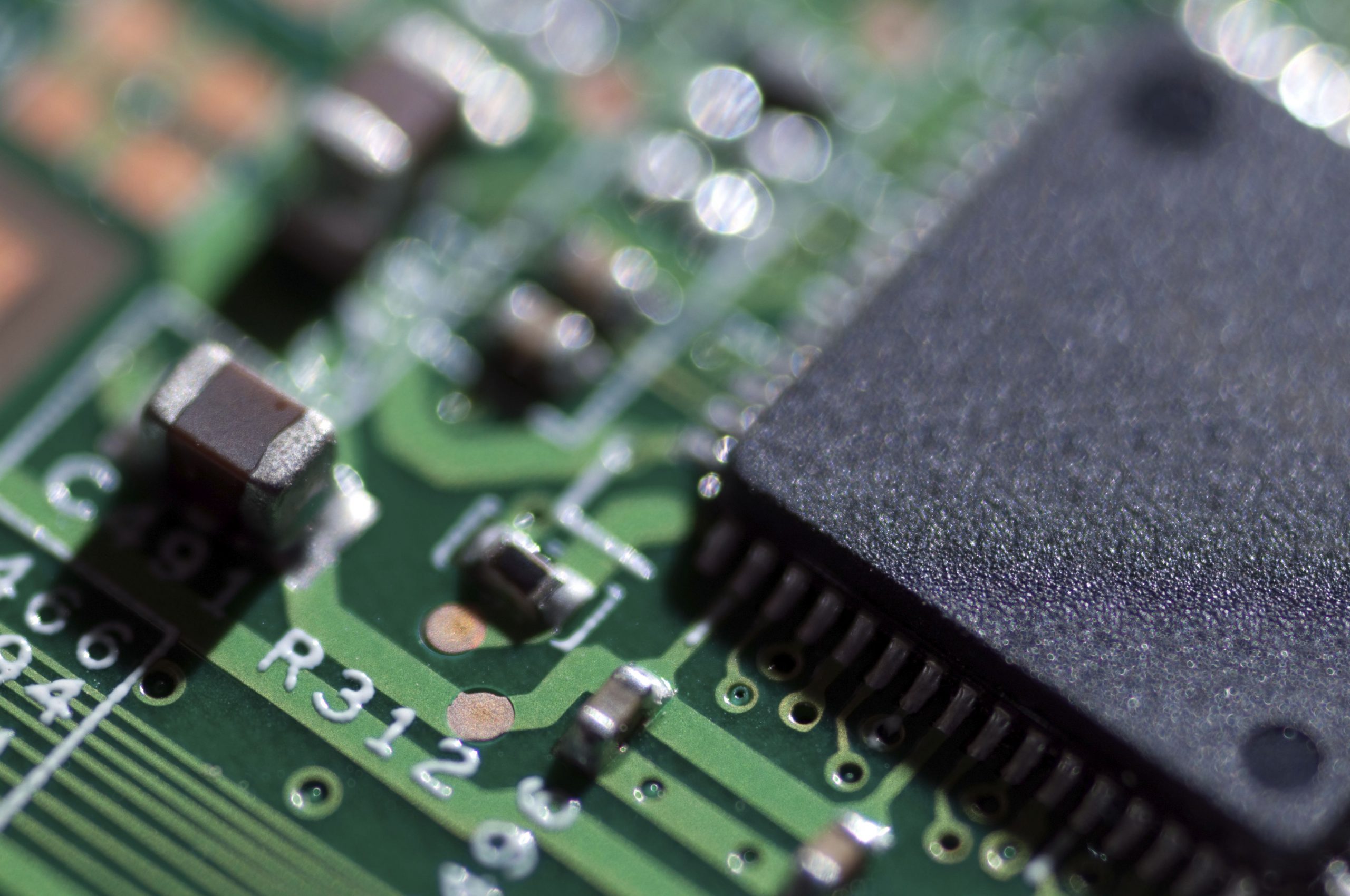

Constant protection with Duresco epoxy moulding compounds

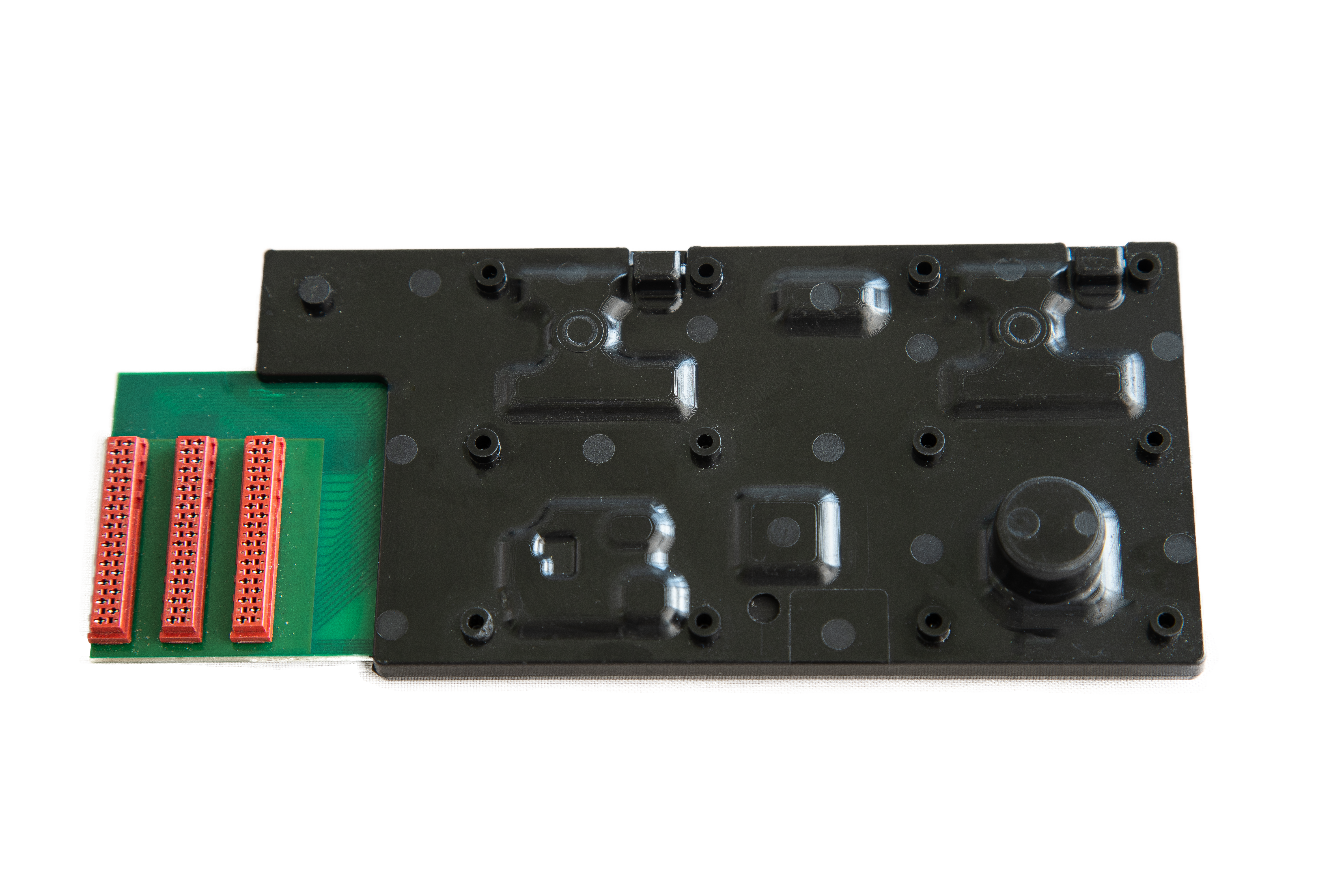

Epoxy moulding compounds from Duresco have a low viscosity and are injection moulded at moderate cavity pressures. This ensures non-damaging, hermetic encapsulation of electronic components, thereby providing lasting protection against damp and other aggressive media, even under challenging climatic conditions. Thanks to automated injection moulding, cycle times are short and therefore economically efficient.

BENEFITS DURING PROCESSING

- Moderate injection pressures

- High flow-path/wall-thickness ratios

- Moulding temperature adjusted to inserts

- Limited mould shrinkage and minimal post-mould shrinkage

- No post-curing required

BENEFITS IN END PROPERTIES

- Low water absorption combined with outstanding chemical resistance

- Good adhesion to surrounding parts

- Hermetic encapsulation

- High thermal shock resistance

- Thermal expansion and thermal conductivity tailored to requirements

- Suitable for 3D MID applications

SUCCESS STORY:

-> Success Story AdTimeCONTACT

Hans-Fred Buchmann

+41 61 726 62 20

hans-fred.buchmann@duresco.ch