Epoxy moulding compounds from Duresco offer high dimensional stability

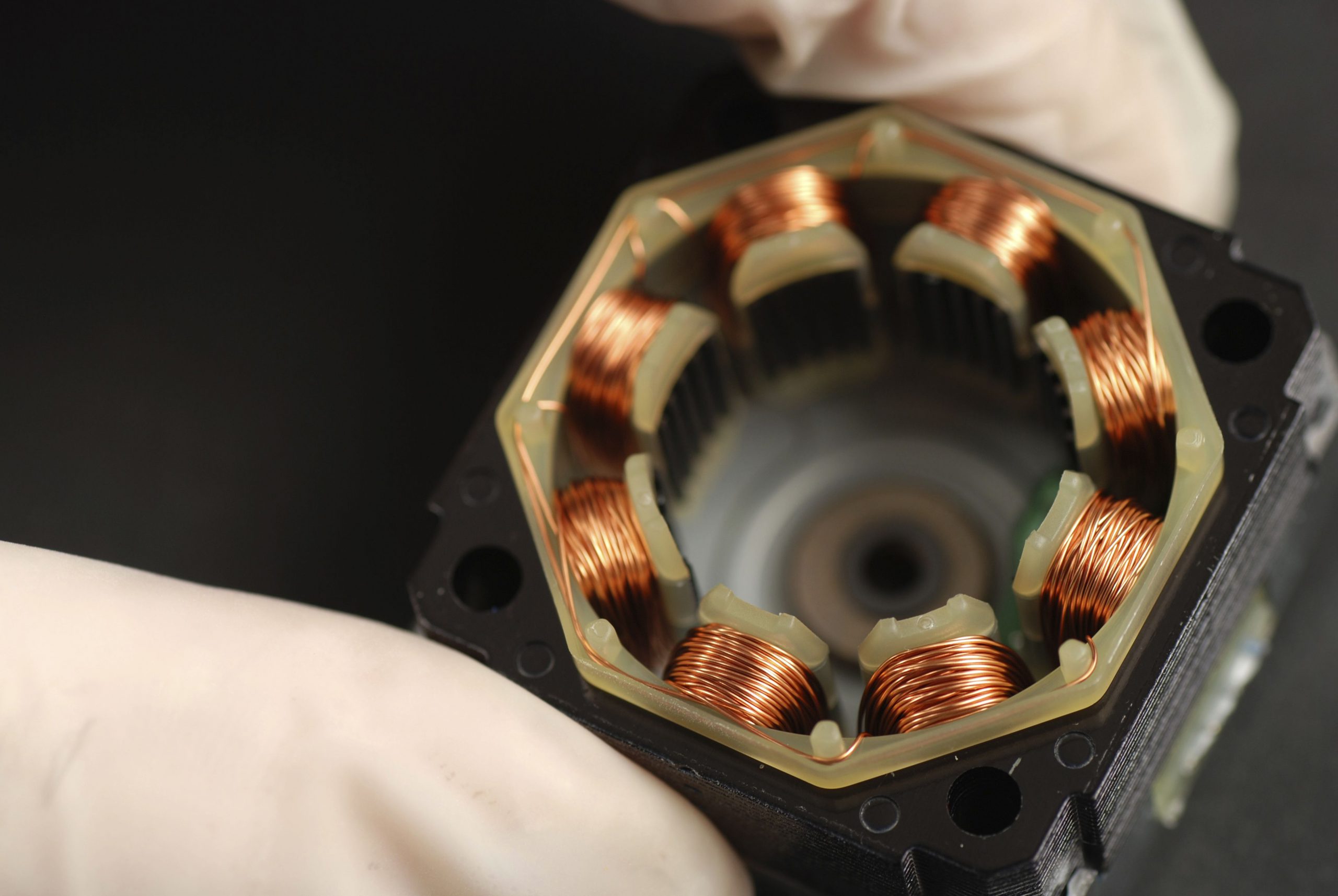

In an electric motor, the commutator and laminated core must be mounted in materials with a high degree of dimensional stability, even at elevated temperatures. In addition, such materials must possess good electrical insulating properties and high crack resistance. These specific material properties help improve motor efficiency and thereby save energy. Epoxy moulding compounds from Duresco meet these exacting specifications and are therefore ideal for high-grade applications.

BENEFITS DURING PROCESSING

- Moderate injection pressures

- High flow-path/wall-thickness ratios

- Limited mould shrinkage and minimal post-mould shrinkage

- No post-curing required

- No emissions during curing

BENEFITS IN END PROPERTIES

- High dimensional stability and temperature resistance

- Good adhesion to the laminated core and housing

- Hermetic encapsulation

- Outstanding resistance to coolants

- Customized thermal conductivity

CONTACT

Hans-Fred Buchmann

+41 61 726 62 20

hans-fred.buchmann@duresco.ch